Flame-Resistant vs. Fire-Retardant Workwear: What Employers Must Know

In high-risk industries such as oil & gas, electrical utilities, construction, and manufacturing, worker safety is non-negotiable. Among various safety considerations, protective clothing plays a pivotal role in reducing the risk of injury during fire-related incidents. While sourcing protective garments, employers often encounter two terms: flame-resistant vs fire-retardant workwear. Though they may sound similar, they differ significantly in material composition, functionality, and suitability for different working environments.

This article outlines the key differences between flame resistant workwear and fire retardant workwear, helping procurement teams and safety officers make informed decisions.

What is Flame-Resistant Workwear?

Flame-resistant workwear is made from inherently non-flammable fibers. These fabrics are engineered to resist ignition and will self-extinguish once the heat source is removed.

Key Characteristics:

- Made from materials like Nomex, Kevlar, or Modacrylic.

- Flame resistance is built into the fiber structure, not added later.

- Maintains protective qualities for the lifetime of the garment.

- Designed for continuous, high-risk exposure to heat or flame.

Ideal For:

- Oil and gas extraction

- Electrical and utility maintenance

- Welding and foundry operations

What is Fire-Retardant Workwear?

Fire-retardant garments are manufactured from standard fabrics such as cotton, which are chemically treated to reduce flammability. These treatments create a barrier that slows the spread of flames.

Key Characteristics:

- Fabric is treated with a chemical flame-retardant finish.

- Protective capability is temporary and may diminish after repeated laundering.

- Requires strict adherence to care instructions for sustained effectiveness.

- Typically more cost-effective upfront than inherently flame-resistant options.

Ideal For:

- Short-term industrial projects

- Moderate-risk environments

- Workers with limited exposure to fire hazards

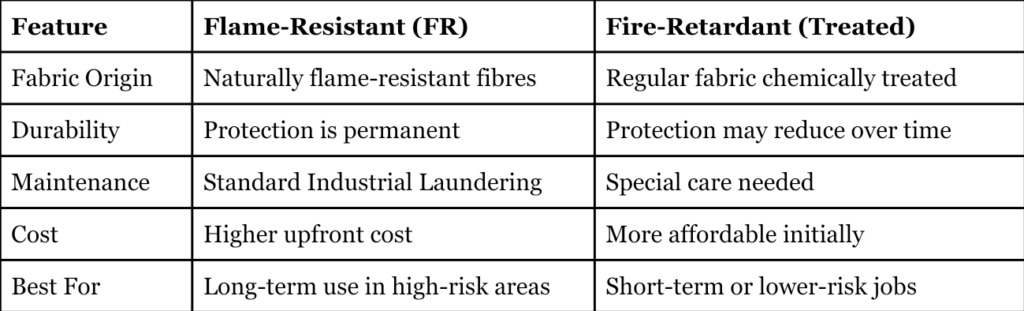

Flame-Resistant vs Flame-Retardant Workwear: Key Differences

Understanding the key differences between flame-resistant and fire-retardant workwear is crucial for choosing the right protection. This quick comparison breaks down their core features to help employers make informed safety decisions.

Why This Difference Matters?

Choosing the wrong type of workwear can put workers at risk.

- In high-risk environments (like refineries or electrical maintenance), flame-resistant workwear is a must.

- In lower-risk settings (occasional fire exposure, lighter industrial work), flame-retardant gear might be sufficient.

Employers must assess the job site risk levels before making a decision.

What Standards Should Employers Check?

Safety certifications ensure that workwear meets industry standards. Look for:

- NFPA 2112: Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire (USA)

- NFPA 70E: Standard for Electrical Safety in the Workplace

- EN ISO 11612: Protective clothing against heat and flame (Europe)

Unito designs its flame-resistant workwear to meet or exceed these safety benchmarks, giving businesses peace of mind.

Cost vs Safety: What Should You Prioritize?

While flame-resistant gear costs more upfront, it offers:

- Longer garment life

- Consistent protection

- Lower replacement costs over time

Fire-retardant garments cost less upfront but may require more frequent replacement, especially if you don't maintain them properly.

Safety should always be the top priority. A single fire incident can cause severe injuries, operational shutdowns, and financial loss far greater than the investment in quality workwear.

Practical Guidance for Employers

With various options available in the market, employers must take a structured approach to ensure the selected garments truly meet the demands of their environment.

Here’s a quick checklist to guide your decision-making process and help you avoid costly mistakes:

- Conduct a risk assessment to identify flame hazards.

- Determine exposure frequency to heat or open flame.

- Check compliance requirements for your industry or region.

- Evaluate total cost of ownership, not just initial pricing.

- Train employees on care and maintenance for optimal protection.

Unito: Your Partner in Industrial Flame Safety

Every employer committed to worker safety must understand the difference between flame-resistant workwear and fire-retardant workwear. Choosing the appropriate protective gear reduces risk, supports compliance, and enhances operational confidence.

At Unito, one of the leading workwear manufacturers in India, we are committed to providing high-quality flame resistant workwear and fire retardant garments that meet international safety standards - ensuring both compliance and worker confidence on every job site.

Read more : Flame-Resistant Vs. High-Visibility Workwear: The Best Fit For Indian Industry